BP Tronic

Full electric press for low-pressure casting of aluminum.

Productivity

Usability

Savings

Final product

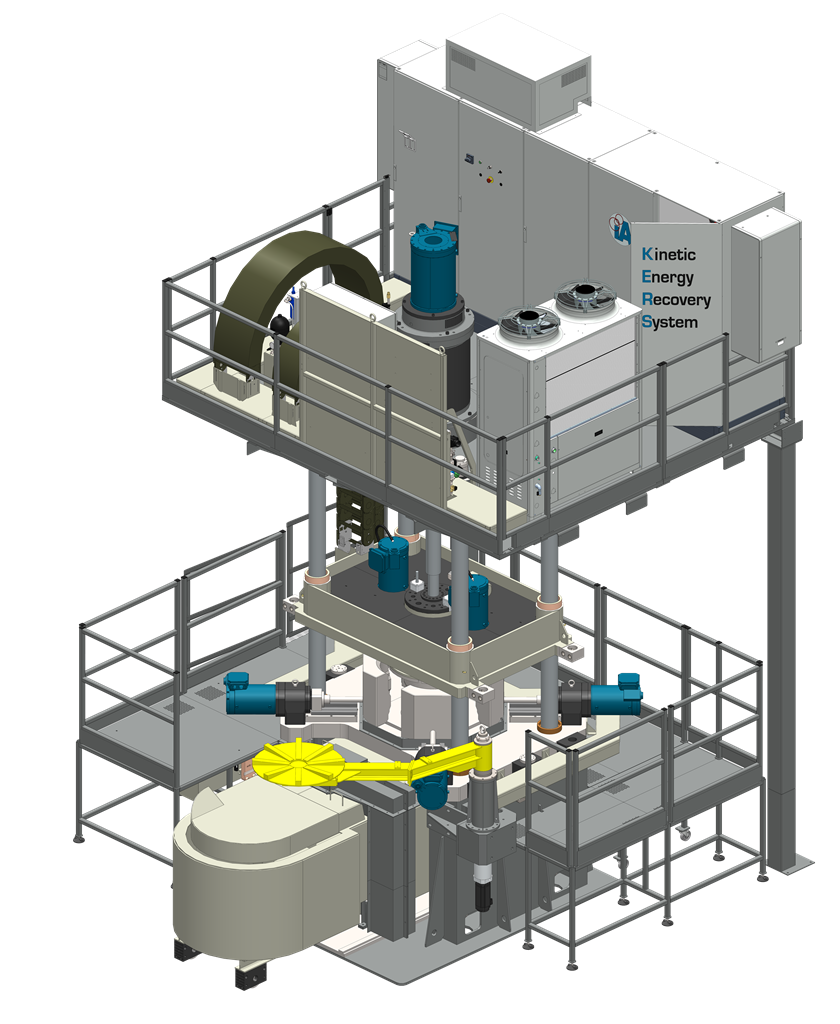

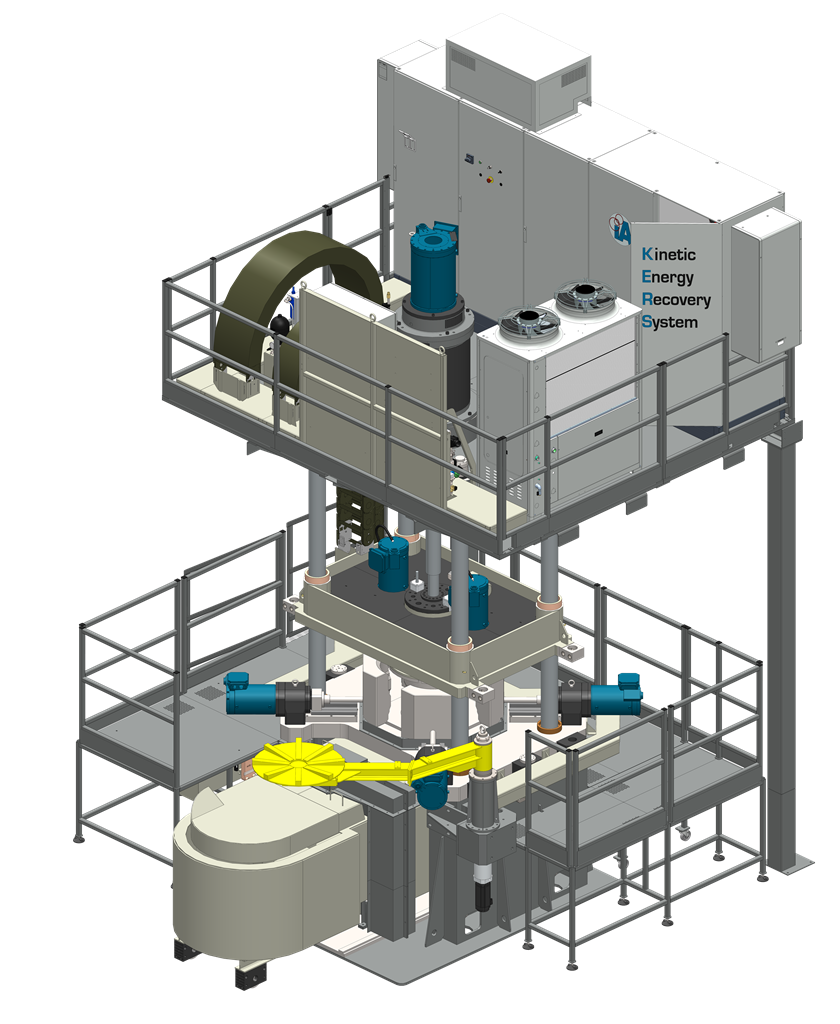

BP Tronic is the one and only low-pressure casting press entirely driven by full-electric motors that applies a completely innovative and revolutionary concept and method.

This press is equipped with a vertical screw closure unit with direct-drive transmission, driven by a torque motor, plus four horizontal axes arranged at 90°driven by screws and nuts always with direct-drive transmission and torque motors.

Because of its unique features, the press offers several advantages over rival state-of-the-art technology. The most important one is the possibility to control the start and stop of each single horizontal axis individually. For instance, we can set up their starting sequence according to preset delays (time) or according to preset measurements (distance).

We can also setup the end position of the horizontal axes in two ways: simultaneous end position of the four axes (interpolation of the axes) or free end position, that is, the first axis to start is the first to arrive.

There are considerable advantages compared to traditional technologies, in particular the possibility of adjusting each axis independently in terms of speed, position and possible sequence in terms of arrival, as well as the positioning repeatability guaranteed by a CNC control, even when temperatures vary, which is a normal variable in the foundry sector.

A wide range offunctionscan be achieved and monitored, since the BP Tronic press is equipped with a real CNC controller, as well as sensor technology and specific algorithms to perform process control during the work phase.

Download brochure

This press is equipped with a vertical screw closure unit with direct-drive transmission, driven by a torque motor, plus four horizontal axes arranged at 90°driven by screws and nuts always with direct-drive transmission and torque motors.

Because of its unique features, the press offers several advantages over rival state-of-the-art technology. The most important one is the possibility to control the start and stop of each single horizontal axis individually. For instance, we can set up their starting sequence according to preset delays (time) or according to preset measurements (distance).

We can also setup the end position of the horizontal axes in two ways: simultaneous end position of the four axes (interpolation of the axes) or free end position, that is, the first axis to start is the first to arrive.

There are considerable advantages compared to traditional technologies, in particular the possibility of adjusting each axis independently in terms of speed, position and possible sequence in terms of arrival, as well as the positioning repeatability guaranteed by a CNC control, even when temperatures vary, which is a normal variable in the foundry sector.

A wide range offunctionscan be achieved and monitored, since the BP Tronic press is equipped with a real CNC controller, as well as sensor technology and specific algorithms to perform process control during the work phase.

Download brochure

Advantages

Ease of use (modern and intuitive HMI)

Full-electric (high flexibility, accuracy and repeatability)

Energy saving (KERS system)

Customizable (100% know-how by Automazioni Industriali)

CNC technology (absolute repeatability and process control)

Synchronization (optimization of operations)

Fast cycle times

Algorithms (control, supervision and management of key process parameters)

Compact layout